Precision’s Role in Sheet Metal Fabrication in Melbourne

When it comes to sheet metal fabrication in Melbourne, precision is an indispensable element that can define the quality and functionality of the end product. Our city, being a hub for various industries such as aerospace, automotive, and lighting, understands the significance of precision in sheet metal fabrication. In this vibrant city, high-quality sheet metal work is paramount for ensuring efficient operations across different sectors. This is where Beta Metal Spinning Co comes into play, setting the standard for precision-driven fabrication.

Understanding Sheet Metal Fabrication

Sheet metal fabrication involves transforming flat sheets of metal into desired shapes and structures through cutting, bending, and assembling processes. Precision in this context means creating parts with accurate dimensions and ensuring consistent quality throughout the production run. Whether you need metal parts for industrial machinery or decorative elements for domestic use, precision is what guarantees durability, performance, and aesthetic appeal.

Moreover, the choice of material plays a vital role in the success of sheet metal fabrication projects. Different metals such as steel, aluminium, copper, and brass offer varying properties including strength, malleability, corrosion resistance, and electrical conductivity. Selecting the appropriate metal based on the application's requirements ensures the end product not only meets functional demands but also withstands environmental conditions.

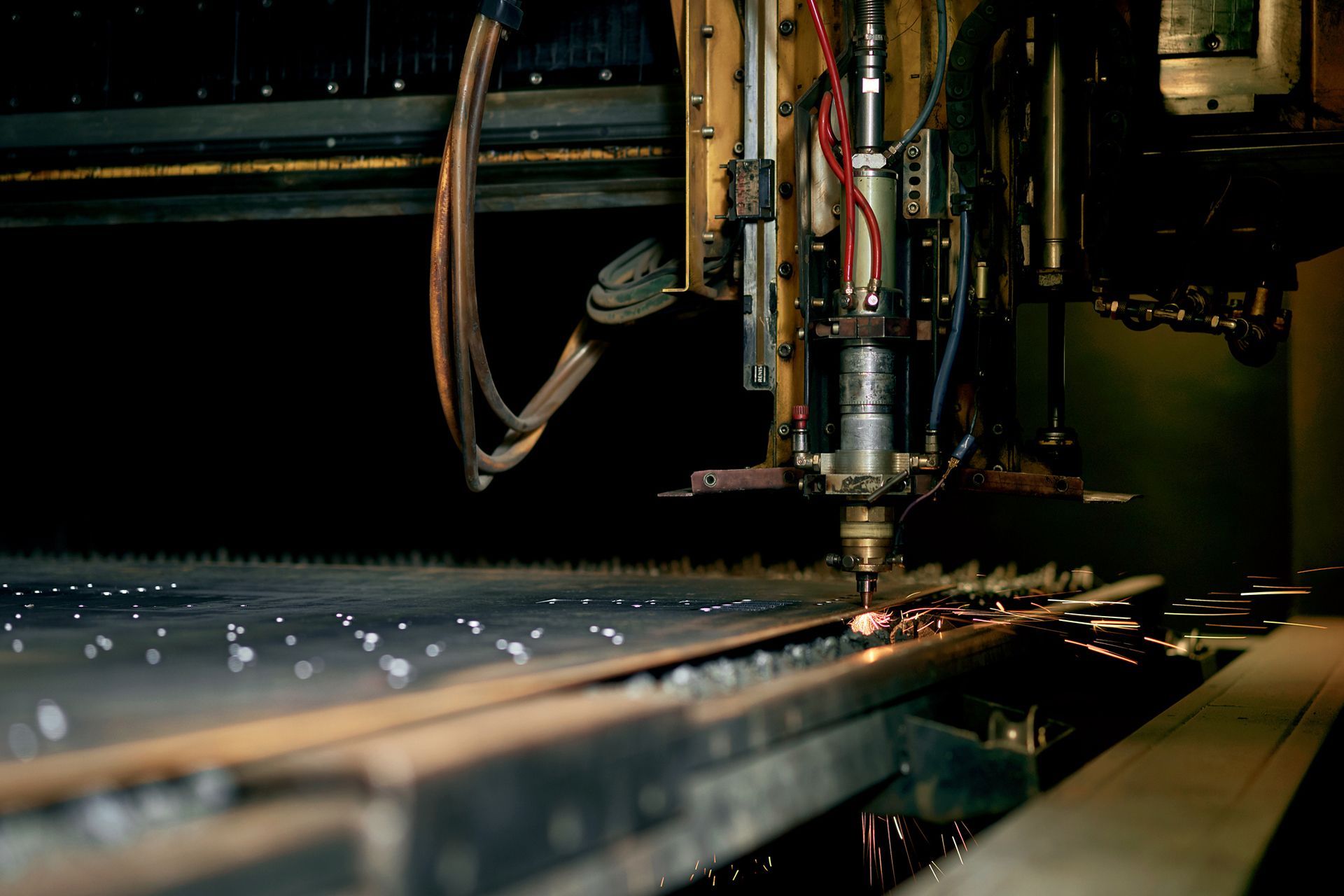

Advanced techniques like laser cutting, CNC machining, and automated welding have revolutionised the fabrication process, enabling complex and intricate designs to be executed with unprecedented accuracy and efficiency. The advancements in technology have also minimised material waste and reduced production time, making sheet metal fabrication a cornerstone of modern manufacturing.

Why Precision Matters in Aerospace Applications

In the aerospace industry, precision is not just a requirement; it is an absolute necessity. Components used in aircraft and spacecraft must adhere to the highest standards of accuracy and reliability to ensure safety and optimal performance. Beta Metal Spinning Co leverages advanced technology and skilled tradespeople to deliver precisely fabricated parts that meet the stringent demands of aerospace applications. From engine components to structural elements, our precision in sheet metal fabrication ensures that every piece integrates seamlessly, contributing to the overall integrity and safety of the aircraft.

Imagine an aerospace manufacturer in Melbourne requiring turbine blades with exact specifications. Our commitment to precision guarantees that these blades are crafted to perfection, ensuring optimal performance and safety at high altitudes.

Precision in Automotive Applications

The automotive industry relies heavily on precision for fabricating parts such as chassis components, exhaust systems, and body panels. Accurate fabrication in these areas enhances the performance, safety, and aesthetic appeal of vehicles. Our skilled tradespeople ensure that every component is fabricated with meticulous attention to detail in sheet metal fabrication, meeting the high standards of automotive manufacturing.

Consider a car manufacturer in Melbourne needing custom exhaust systems. With our precision-driven fabrication, these systems are optimised for performance and efficiency, resulting in quieter, more fuel-efficient vehicles that meet emission standards.

Lighting Industry: A Beacon of Precision

Precision is equally critical in the lighting industry, where high-quality fixtures must be both functional and visually appealing. From commercial lighting solutions to decorative domestic fixtures, Beta Metal Spinning Co employs advanced technology in

metal fabrication to ensure that every product is crafted with accuracy and consistency. Our skilled tradespeople work diligently to create lighting components that meet the highest standards of quality and design.

Picture a lighting company in Melbourne requiring custom metal fixtures for an upscale hotel. Our precision ensures that these fixtures not only illuminate spaces effectively but also contribute to the aesthetic ambience, enhancing the overall guest experience.

Technological Advancements Ensuring Precision

Beta Metal Spinning Co utilises cutting-edge fabrication technology, including CNC machines and laser cutting tools, which have revolutionised the sheet metal fabrication industry. These technologies enable our fabricators to achieve unparalleled precision and consistency in their work. CNC machines operate based on computer-aided design (CAD) files, ensuring every cut and bend adheres to exact specifications. Similarly, laser cutting tools provide clean, precise cuts, reducing the margin of error and enhancing the quality of fabricated components.

A Commitment to Quality and Precision

At Beta Metal Spinning Co, we pride ourselves on our commitment to precision and quality in every project. Our team of skilled tradespeople brings a wealth of experience and expertise to the table, ensuring that each component we fabricate meets your exact requirements. Whether you are in the aerospace, automotive, or lighting industry, we provide the precision-driven solutions you need to succeed. Read more about us in our company profile.

Ensuring Precision for Quality Results

For businesses and homeowners in Melbourne seeking high-quality sheet metal fabrication, precision should be a top priority. It’s the key to ensuring that every component is reliable, durable, and aesthetically pleasing. Whether you need commercial fixtures, industrial machinery parts, recreational equipment, or domestic items, choosing a reputable fabricator who prioritises precision can make all the difference.

Get Quality Results Today!

If you require expert sheet metal fabrication in Melbourne, reach out to Beta Metal Spinning Co. Our team is dedicated to delivering precise, quality results tailored to your specific needs. Contact us today to discuss your project and see how our precision-driven approach can benefit you.