Metal Spinning Services Melbourne Delivering High Quality CNC Spinning Works

Get that smooth, sleek finish with our professional Metal Spinning Services in Melbourne. We have been helping the public and businesses across Melbourne for over 40 years with all their CNC Spinning requirements. Our machines are of the highest standard, versatile & capable of bringing any plans to life. Let our experienced team here at Beta Meal Spinning Services help you. We can easily include spun metal components into your assembly requirements delivering a high-end finish with price precision.

So How Does Metal Spinning Work?

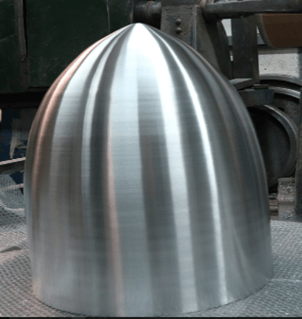

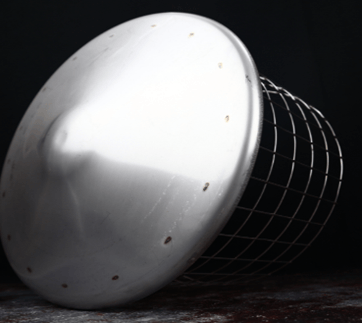

During the spinning or spin forming process, sheet metal is rotated while forces are applied to a single side. CNC programmes are passed over the roller, and the material gradually assumes the desired shape for the project. In this method, the desired shape can be formed with great precision, and it will not damage the integrity or quality of the metal. The metal spinning process can produce almost any type of hollow body, including objects with very complex geometry & narrow tolerance. Simply by using both high-speed rotation and force, metal spinning forms symmetrical, conical, or cylindrical shapes. Depending on the volume of products you require, it can be done by hand or machine.

Benefits of Metal Spinning

- Short Turnaround - metal spinning has a fast turnaround time, with significantly lower initial investment costs.

- Lower Tooling Cost & Increased Tooling Flexibility - saving you money and time

- Ease of Design Change - changes in the partway production stage can often be made through changes in tooling

- Ability to produce sleek spun shapes faster than any other machines

- Small to Large Volume - Beta Metals proudly offer customer prototypes to total volume production capacity. Both manual and semi-automated equipment can be used to handle prototype or small production runs.

- Products are solid and reliable.

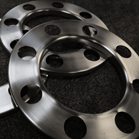

- Multi-Process Production: Metal spinning can be combined with other processes such as deep drawing, rolling, and welding to manufacturing challenging designs. We routinely produce quantities of assemblies made from 4 or 5 different spun components.

- Improved Metallurgy. - Metal Spinning, compared to other technologies, improves metallurgy by realigning the metal's grain structure. Tensile strength is improved, allowing lighter gauge material to be used in similar applications.

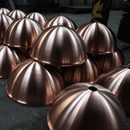

- We can spin many types of metals – as most metals available in sheets can be spun, the most commonly used are: Aluminium, Copper, Brass, Stainless Steel, and Carbon Steel.

Let us help you decide if metal spinning is the proper manufacturing process for your part.

Applications Metal Spinning Is Used In

- Lighting

- Industrial Applications

- Architectural & Constructions

- Oils, Gas and Defence industries

- Bespoke Projects - Metal spinning applications never end with various uses, trophies, decorative bowls, sculptured pieces and much more.

- Air Handling - Metal Spinning is excellent for producing outlets for HVAC systems ranging from endcaps and flanges.

From all types of metal across various industries, metal spinning can be found in the most unlikely places.

We provide a number of manufacturing solutions for engineered components

Talk to Beta Metal Spinning Services Today

Browse Our Website

Contact Information

Landline: 03 9555 8444

Email: bms@betametal.com.au

Business Hours

Monday - Friday 7:00 AM - 4:00 PM

ABN: 38334255297

INVOICE

Our Service Location

We are central base in Melbourne & service all of Melbourne & regional Victoria, as well as interstate.